About 10 years ago, two Wisconsin extension agents initiated a study where they went from farm to farm and weighed large round bales using portable pad scales. Before determining the actual weights, the agents and the farmer took a crack at estimating the average bale weight (three bales were weighed at each farm).

The combined guess of the extension agents and farmers missed the actual average bale weight by 100 pounds, sometimes being over and other times being under the true weight. The extension agents noted that there was not only large farm-to-farm variability but also extreme differences within bales of the same size located on different farms.

Over or underestimating the weight of a bale can have severe consequences when buying, selling, or feeding hay. Still, we see a lot of hay prices being quoted by the bale, which isn’t necessarily bad if both buyer and seller also know the exact average weight of the bales being sold. It’s equally important if the bales are being fed on the farm where they were made. It’s never a welcomed surprise to run out of hay before green pastures appear.

The list of factors that can influence the weight of a large round bale goes well beyond just bale size and density, although those are critical. There is also bale moisture, time elapsed since harvest, where the bale was stored, type of hay, forage maturity, and the model and age of the baler to consider.

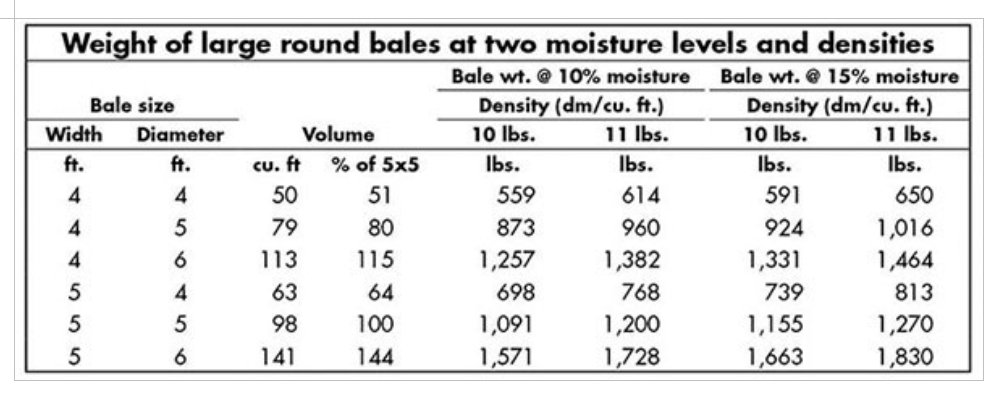

Without question, bale size will impact bale weight, but what may be overlooked is the degree of change that occurs when a bale is only 1 foot wider or 1 foot more in diameter. The latter accounts for the largest change. For example, a 4-foot-wide by 5-foot-diameter bale (4×5) has 80% of the volume of a 5×5 bale (see table below). However, a 5×4 bale has only 64% of the volume of a 5×5 bale. Those percentages also translate to big differences in weight if all other factors are equal.

Bale density plays a rather large role in final bale weight. It often ranges from 9 to 12 pounds per cubic foot. In a 5×5 bale, the difference between 10 and 11 pounds of dry matter per square foot amounts to over 100 pounds per bale at both the 10% and 15% moisture levels. Missing the weight of a bale by 10% amounts to a lot of dollars if multiple tons are being purchased or fed.

As seen in the table, forage moisture also plays a role in bale weight but to a lesser degree than bale density unless bales are extremely dry or wet. Wrapped bales, for example, can vary in moisture from 25% to over 60%. When purchasing baleage, it is always recommended to weigh the bales and have an accurate moisture test. Water should cost less than forage dry matter.

Time of purchase impacts bale weight in two ways. First, if you’re purchasing bales out of field, they are likely going to be at a higher moisture level and weight than they will be after being cured in storage. Also, there is a natural tendency for dry matter to be lost during storage that the buyer will incur if bales are purchased directly out of the field. As has been well documented by research, storage losses can range from below 5% to over 50%, depending on storage method.

Bales stored outside for a long duration can vary drastically in both forage quality and weight, depending on how they were oriented and stacked. Loss of dry matter impacts weight but so does excessive water infiltration into a bale.

Forage species also affect bale weight. Grass bales generally will weigh less than legume-dominant bales of similar size. This is because legumes such as alfalfa will make a denser bale than a grass species. A grass bale will often weigh 100 pounds or less than a similar-sized legume bale.

Plant maturity is another factor that impacts bale density and ultimately bale weight. Leaves generally pack better than stems, so as plants mature and develop a higher percentage of stems to leaves, bales generally become less dense and weigh less.

Finally, there are many models of balers of differing ages. This variation, coupled with operator experience, lends further variability into the bale density and weight discussion. Some new balers are specifically designed to make high-density bales that will weigh more than a typical bale.

Weighing bales is less convenient than not weighing them, but there are few situations where it won’t pay dividends. In most cases, not every bale has to be weighed if bales within a lot are similar. Bale weight guessing is only a good exercise if you do it prior to driving over a scale.